Glossary of terms used in the trade shared to create a common understanding. Also see Crane Industry Abbreviations and their meanings.

- Boom

- A boom is the lifting arm of the crane. Booms can be static (fixed length), or telescopic with multiple extending sections that lock into place to increase the length of the boom. A longer boom gives the operator more height or radial reach from the crane’s position.

- Dynamic Load

- The additional load created by a force being applied to the Gross Load. eg. the force required to start and stop a mass from moving in a single direction.

- This can sometimes occur when a load is being transferred off a moving surface like a boat deck. The average wave height when unloading vessels in the North Sea is around 3m. If a cargo load is hoisted at the wrong moment, the resulting shock load will create a dynamic effect that can increase the load on the crane by up to three times the actual gross weight.

- Eye

- A loop at the end of a line (cable,chain,rope) that can be attached to a hook.

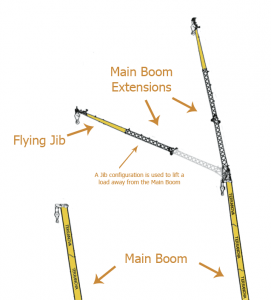

- Fly Jib

- A Flying Jib is the last section (tip) in a crane’s boom (or extended jib) that acts as a jib.

- Gross Capacity

- Is the max mass/weight that can be lifted by the crane at the end of its lifting line when it is vertical (straight down with no side lift). This includes the weight of the hook and block, any lifting accessory used and the load itself.

- Gross Load

- The overall load lifted by a crane’s lifting line and boom. This is the value to be used against a Manufacturer’s Lifting Chart.

Gross Load = Net Load (item being lifted) + Lifting Gear and Accessories

- Ground Bearing Capacity (GBC)

- The capacity of the soil or ground to carry a load (quantified as pressure) without producing a shear failure. For cranes, the GBC for every outrigger (or point of contact with the ground) should have the capacity to bear the full weight of the crane, its rigging, and its load.

- Hitch

- The line(s) (cable,chain,rope) used to attach a load to the hoist.

All our crane operators are trained to know which type of hitch line and method best to use to safely lift any load.

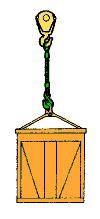

Basic types of hitches- Straight Hitch (or Vertical Hitch)

-

Straight Hitch A straight hitch uses a single piece of line (webbing or chain) where one eye is connected to the lifting hoist and the other eye clips to a piece of webbing or other attachment point on the load. This type of hitch is rarely used for lifting, as the load tends to turn and spin upon lifting, making it tough to control large, heavy loads at height.

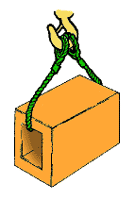

- Basket Hitch

-

Basket Hitch A basket hitch cradles the load by attaching both eyes of the sling to the overhead cable. This type of hitch can be used as either a single, double wrap. Basket hitches cannot be used with loads that are difficult to balance.

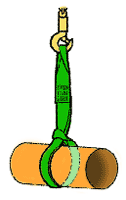

- Choker Hitch

-

Choker Hitch A choker hitch tightens as the load is lifted helping to guard against slippage and load loss. One eye of the hitch is passed through the other. With this type of hitch, a webbing strap/sling is normally used. Variations on the single choker hitch include the double choker hitch, and the double wrap choker hitch, both provide greater contact area to better secure the load, increase control during movement, and prevent slippage from the sling.

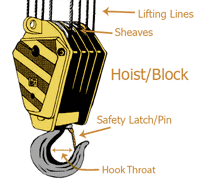

- Hoist (or block)

A frame consisting of a hook and lower sheave(s) which the overhead hoist line is fed through.

A frame consisting of a hook and lower sheave(s) which the overhead hoist line is fed through.- Hoist Line

- The wire cable (rope) used to lift the load. Normally constructed from multiple strains of high tensile steel wire.

- Jib

- A Jib or Jib arm is a beam used by many types of crane to support a wide load clear of the main supporting boom. A main boom extension can sometimes be used as a Jib to extend it and therefore the distance of the load from the main boom. The use of a jib normally lowers the safe maximum lifting capacity of a crane. This can mean wide loads may need a high capacity crane even though the load itself is not heavy. Please contact us for further information.

- Lift Distance

- The Lift Distance is measured from the centre pin of the crane’s boom to the centre of the load.

- Jib Hoist

- The lifting mechanism which the lifting cable is fed through via the jib beam.

- Lift Plan

- see Method Statement

- Load Weight

- The static weight of the item to be lifted by the crane. (Also See Net Load & Net Capacity)

- Luffing

-

Luffing Jib by Silberwolf A crane mechanism where the hook remains at the same level whilst the main boom is moved up or down.

- Main Hoist Line

- The lifting wire rope fed via the main boom.

- Method Statement (Lift Plan, RAMS)

- A document detailing the type of lift required, site access, GBC assessment, all the equipment and personnel required.

- Minimum Breaking Load / MBL

- The load at which a piece of equipment is expected to fail by its manufacture.

- Net Capacity

- Is the max mass/weight (of the item) that can be lifted by the crane which is not part of the lifting configuration (everything else needed to lift the required item).

Net Capacity = Gross Capacity – Lifting Gear and Accessories - Net Load

- The mass/weight of the item being lifted.

- Net Load = Gross Load – Lifting Gear and Accessories

- Overhead Cable

- The lifting cable coming from the crane’s boom.

- Peak Load

- Peak Load = Gross Load + Maximum Dynamic Load

- Rated Capacity

- Rated Capacity is the maximum total load a crane can lift under a set configuration. Rated Capacity is also known as the Maximum Rated Capacity (MRC) or Manufacturer’s Rated Capacity. As defined in BS EN 13000:2004 (Cranes – Mobile Cranes), Rated Capacity is “load that the crane is designed to lift for a given operating condition (e.g. configuration, position of the load). For mobile cranes the mass (weight) of the hook block is part of the load”

- Risk Assessment & Method Statement (RAMS)

- Method Statement and assessment of the risks involved. See Method Statement

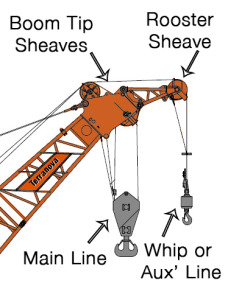

- Rooster Sheave

An auxiliary lifting sheave at the boom tip used to provide an additional whip line or auxiliary line in support of the main line.

An auxiliary lifting sheave at the boom tip used to provide an additional whip line or auxiliary line in support of the main line.- Rope Lay

- The distance necessary to complete one turn of the strand around the diameter of a wire rope (cable). A wire rope is normally made up of strains, each strain is made up of several high tensile steel wires wound around a single core wire. A running cable (eg. hoist line) with 6 or more broken wires in single rope lay length, or 3 or more broken wires in one strand in one rope lay length is not fit for further use and should be replaced. All our equipment is checked before each working day to ensure it is fit for purpose and safe to operate.

- Sheave

- A pulley wheel with a groove for holding a wire cable or rope (line). The grooved wheel spins on an axle inside the frame of the block. This allows the line to move freely minimising friction and wear on the cable. Sheaves can be used to redirect a cable or rope, lift loads, and transmit power.

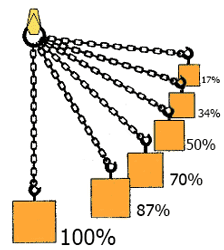

- Sling Angle

-

How the Sling Angle effects the maximium load lifted The tension on a hitch increases as the angle from the lifting hoist to load increases. With a Straight Hitch a line can lift 100% of its rated load. With a Basket Hitch, due to the angle of lift creating side tension in the hitch lines, the maximum load (working load limit, WLL) a line can carry vertically up dramatically decreases as the angle towards 90 degrees of the lift line (vertical) increases. All our crane operators are trained to know which hitch method and lines are best to use to safely lift any load.

- Strand

- A wire rope is normally made up of twisted strands, each strand is made up of several high tensile steel wires wound around a single core wire.

- Safe Working Load (SWL)

- UK’s HSE definition of Safe Working Load is “a value or set of values based on the strength and/or stability of the equipment when lifting.” (Lifting Operations and Lifting Equipment Regulations 1998). A piece of equipment can have more than one SWL depending on the lift configuration used. A SWL is expressed as the maximum load a piece of equipment can safely lift in a predefined configuration. The USA, Europe, UK & Australian standard bodies have deprecated the use of this term in favour Rated Capacity for cranes and Working Load Limit for lift gear and accessories.

- Tip Sheave

- The grooved wheel feeding the hoist line from the tip of the Boom or Jib. Also see Sheave.

- Ultimate Load

- See Minimum Breaking Load / MBL

- Whip Line (Auxiliary Line)

- An additional single line that can be used to lift lighter loads more quickly than the main line, especially if the main line is made up of multi wire cables. Multi cables means a heavier load can be lifted, however more slowly. A whip line improves work efficiency when a range of loads is expected.

- Working Load

- Is the “load on the hook plus mass (weight) of the hook and block” (as defined by BS EN 13000:2004). This is everything being lifted by the lift line eg. hook and block, any lift accessories used and the item itself actually being lifted.

- Working Load Limit (WLL)

- Is the maximum working load for an accessory under a set configuration for normal working conditions. The lowest WLL for any component(s) within a lift configuration determines the overall Gross Capacity for that configuration.